Amsterdam University of Applied Sciences (AUAS)

The Amsterdam University of Applied Sciences (AUAS) is a knowledge institution that, by linking education and practice-oriented research, contributes to the renewal of professional practice and society in and around an internationally oriented Amsterdam. The Faculty of Technology is one of the seven faculties of the AUAS and prepares students for a career as an engineer distinguished by a solid technical foundation, problem-solving and innovative skills, entrepreneurship, professionalism and integrity. The faculty is one of the largest in the Netherlands and is committed to knowledge innovation, educational development, applied research and knowledge transfer.

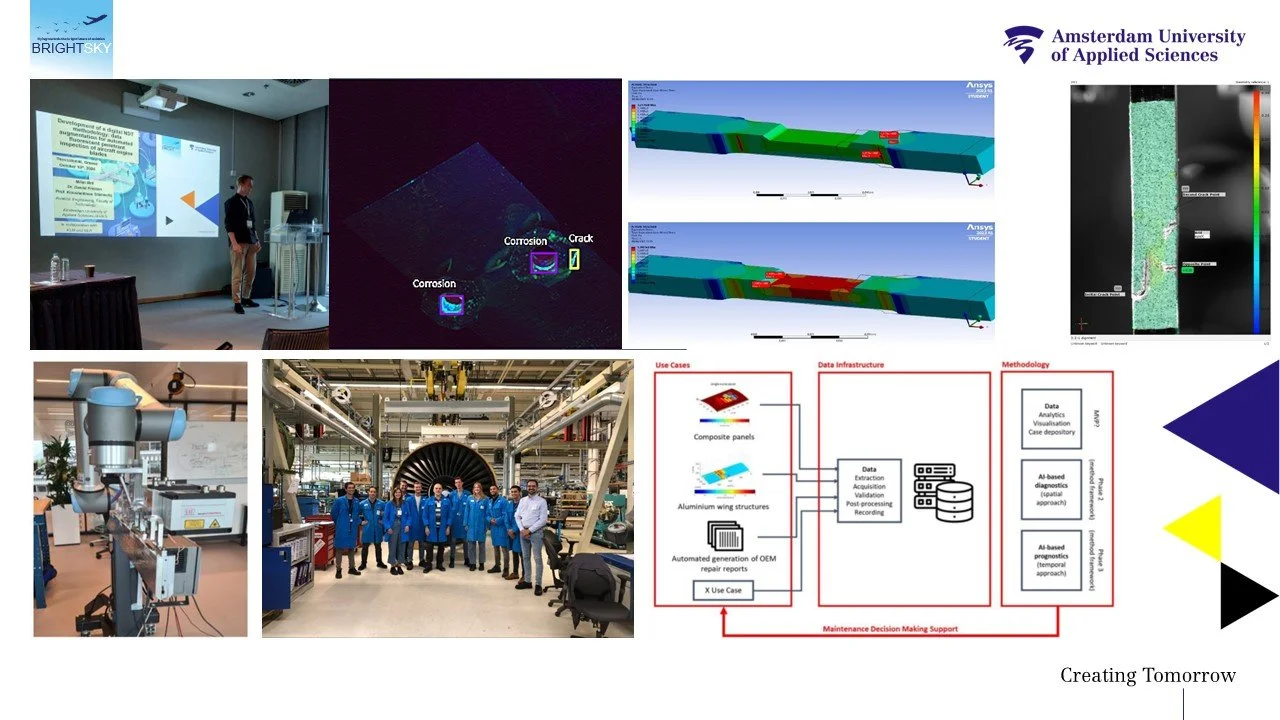

Within Brightsky, the Aviation research group of the AUAS Faculty of Technology is involved as a research partner in the: aircraft MRO relevant projects (Work Packages 1, 2 and 5) and the airport operations and systems projects (Work Packages 3 and 4). In particular and concerning the MRO research projects, the AUAS is investigating different aspects of aviation MRO in terms of novel aircraft inspection and repairs (WP 1), data-driven prognostics, diagnostics and decision support systems (WP 2) and human-computer interface and specifications for professional training with the use of Virtual Reality (WP 5).

AUAS’s contribution to R&D Mobility fund

-

Smart MRO (WP1)

Within WP1 the AUAS Aviation research group is working with TUD, NLR, TNO, S&T, KLM E&M, JetSupport and EPCOR on the development of automated and innovative aircraft inspection and repair methodologies. The introduction of novel repair methodologies such as cold spray or cold metal transfer are promising processes for various aircraft and engine components. Within this part of the project, the AUAS is conducting applied materials research to contribute to the understanding of the failure mechanisms observed during mechanical testing for qualification of a cold spray repair methodology and the interdependencies between the process parameters, the material microstructure, and the targeted mechanical properties.

The development of novel inspection methodologies in the form of automated non-destructive testing aims to significantly reduce the inspection times of components and aircraft structures, providing accuracy and flexibility. Automating parts of existing methods like fluorescent penetrant inspection through robotics and data-based algorithms aims to support aviation inspectors who face sometimes repetitive tasks, rising workload, and a stagnating or shrinking influx of new colleagues. To this end, the AUAS contributes to the development of a cobot-based sensor positioning and steering system, the qualification of novel inspection systems, the development of digital twins and digital tools (conventional and AI-enabled), and systems design and engineering.

-

Smart Availability (WP2)

Within WP2 the AUAS Aviation research group is working with KLM E&M, JetSupport and TU Delft on the development of technologies related to Predictive and Condition-based Maintenance (PdM and CBM, respectively), as well as on Maintenance Scheduling and Optimisation. Within this part of the project, the AUAS is exploring novel data-driven methods for the identification of imminent maintenance actions, based on reliability analysis and other methods. AUAS is also working on data exchange algorithms towards Federated Learning. This is a technique that could bring a common benefit to partners that are not allowed to share data with each other, but still want to share aggregated information and the expertise contained in the data. Last, the scheduling of maintenance actions and planning of resources is explored on a strategic, tactical, and operational level.

-

Smart Operations (WP3)

Within WP3 the AUAS Aviation research group is working with TNO, Vanderlande, T-Hive, Schiphol, and Jet Support on the development of insight into a possible transition path from current operations to a new concept of operations for a fully autonomous airside in 2050. The transformation to an autonomous airside operation at AAS means a tremendous change in airside operations stakeholders’ processes because it will fundamentally alter the way airside operations are carried out. In the first phase, the introduction of autonomous fleets of vehicles in the transport of baggage containers from the basement in the terminal building to the aircraft parking position and vice versa is analysed. In the second phase, the introduction of autonomous fleets in the transport of passengers from the terminal building to the aircraft is incorporated.

Within this part of the project, the AUAS team as part of the consortium aims to conduct applied research on the Smart autonomous airside work package by analysing three main areas online with the general objectives: the Governance system of the airside, its current characteristics and challenges for the transition to 2050; the Turnaround processes to be automated; and the autonomous multi-fleets of vehicles interact among them.

-

Smart Access (WP4)

Within WP4 the AUAS Aviation research group is working with Stage Gate 11, DT-Solutions, Jet Support, and Schiphol on the development of Optical Trace Detection technology and X-ray Diffraction technology. Passenger numbers are steadily increasing globally and the stress on security checkpoints increases with it. Whilst the passenger experience is impacted by the negative effects of this growth i.e., increased wait times, social discomfort, etc. speed and safeguarding security screening are important factors in the passenger security screening process. Therefore, to ensure more sustainable and secure terminal access, further automation and digitalization are part of the discussion this, together with the needed screening technology. This digitalization will further reduces the chance for human error by employing algorithms and machine learning to accurately and fully automatically analyse scans captured during security screening.

Within this part of the project, the AUAS is focusing on researching the use of next-generation security screening devices in airport operations, especially for the passenger and baggage handling process. We work closely with our industry partners through on requirements and limitations that are involved in implementing new security devices in the daily operations at airports.

-

Smart Training (WP5)

Within WP5 the AUAS Aviation research group is working with the NLR, KLM and JetSupport on the development of a maintenance synthetic training device (MSTD). Training improvements target higher training efficiency in engine start-ups and type training, via the increase of practice frequency in a realistic and safe-to-train (emergency) scenarios. The benefits of the new training environment also encompass sustainability benefits, as there is no need of a physical aircraft and its engines. Within this part of the project, the AUAS is evaluating the training device from a human-centred design perspective. To this end, the AUAS team researches the fidelity requirements of the digital simulator, user acceptance, the training effectiveness and transfer, and the health and safety of the users.