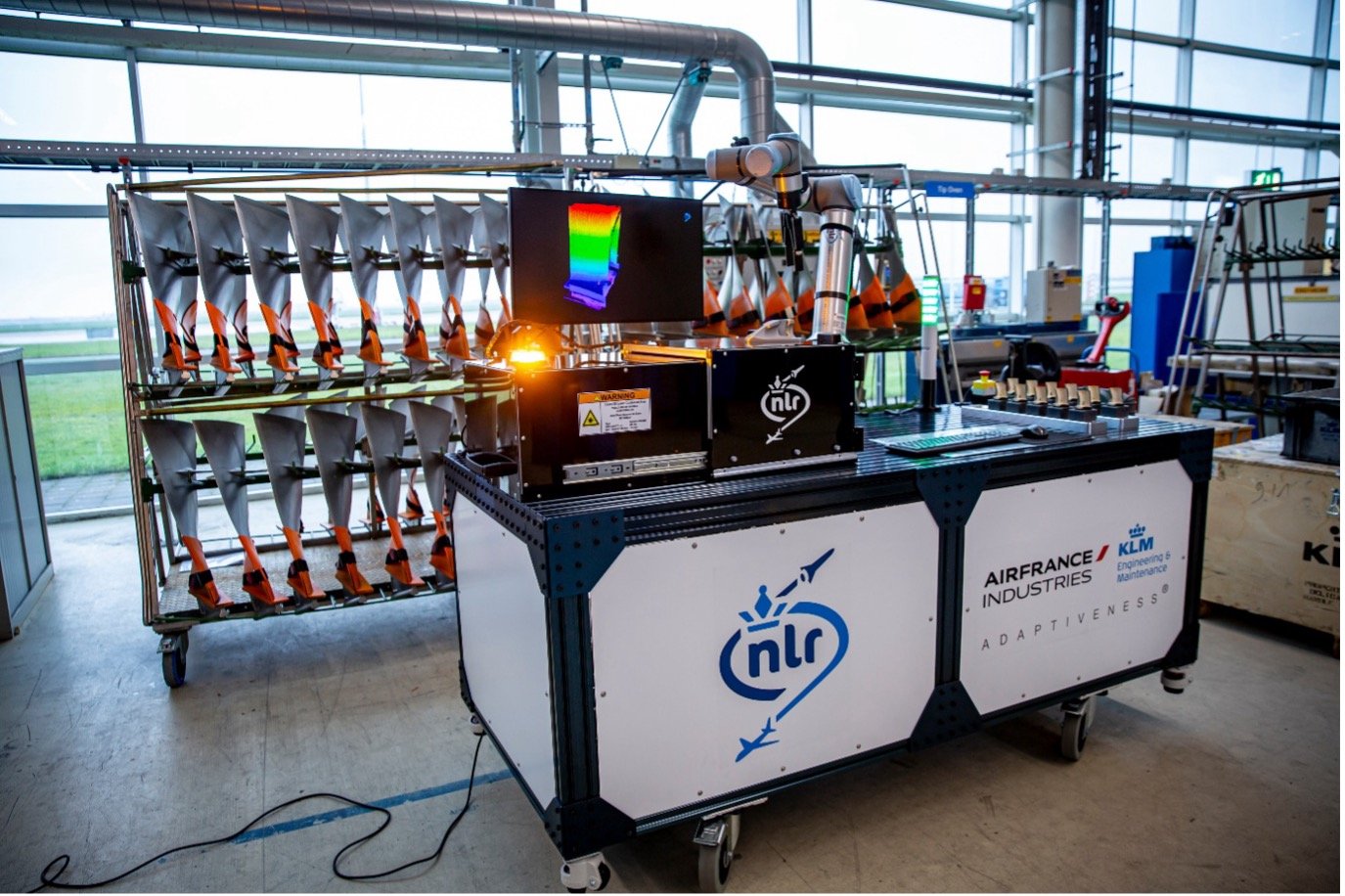

Robotisation for maintenance

Netherlands Aerospace Centre (NLR)

The Royal Netherlands Aerospace Centre (NLR) operates as an objective and independent research centre, working with its partners towards a better world for tomorrow. As part of that, NLR offers innovative solutions and technical expertise, creating a strong competitive position for the commercial sector.

NLR has been a centre of expertise for over a century now, with a deep-seated desire to keep innovating. It is an organisation that works to achieve sustainable, safe, efficient and effective aerospace operations. The combination of in-depth insights into customers’ needs, multidisciplinary expertise and state-of-the-art research facilities makes rapid innovation possible. Both domestically and abroad, NLR plays a pivotal role between science, industry and government, bridging the gap between fundamental research and practical applications. Additionally, NLR is one of the large technological institutes that have been collaborating for over a decade in the Netherlands on applied research.

Link to the website: https://www.nlr.org/mro/

NLR’s contribution to Hyperion

-

Autonomous Sensor (WP1)

In WP1, partners develop a demonstrator stand-alone measurement system to enable prognostics on an aircraft component. The end result of WP1 is a platform-certified and proven applicable demonstrator sensor system that can signal timely necessary maintenance for critical aviation components. Certification of the autonomous measurement system will be performed specifically for an aircraft type and the certification documents will be drawn up for this aircraft type. NLR will contribute to root-cause analysis, measurement system design, certification documents and evaluation of lab/shop/on-wing data.

-

Digital Passport (WP2)

In WP2, NLR contributes to the realisation of a Digital Product Passport (DPP) system by specifying and designing a system and infrastructure for the creation and management of DPPs of aircraft components for the purpose of effective and efficient controlling the maintenance, repair, and overhaul (MRO) supply chain. Activities include (contributions to) investigation of the state-of-the-art, collection and analysis of stakeholder needs, translating the needs to a design and infrastructure, creation of a data model for the DPPs and effective use of digital ledger technology (blockchain), design of applications of the DPPs, design of supply chain management based on the DPPs, and supporting the development of proof-of-concepts, prototypes, and demonstrators.

-

Operating Systems (WP3)

The goal of WP3 is to develop a partially automated Chain Management System by combining the outcomes from WP1 and 2. Our NLR team members contribute to this by adding their knowledge and experience in the field of Smart Contracts, Project Management, Secure Collaboration, and System and tool integration. Furthermore, it is of utmost importance that we also have in-depth knowledge of the topics covered in both WP1 and 2. This will allow us to set up a so called Control Tower (ERP system) that is capable of providing the actors in the Control Tower sufficient and adequate information to get the parts in the right place, at the right time.